When choosing a high performance liquid chromatography (HPLC) system, it's important to consider how your future needs may evolve from your current needs. While integrated HPLC systems are preconfigured for specific purification tasks, many of these types of systems aren't well suited to evolve with future changes in your experiments, and these systems won't be able to take advantage of technological advances. Additionally, many preparative HPLC systems on the market are not flexible enough for CROs/CDMOs and Pharma companies that purify a large number and variety of molecules.

Scientific research is diverse, and requirements can change from one experiment to another. Not being able to mix and match components makes it harder for researchers to adapt HPLC systems easily to different types of purification, sample solubility and volumes, and compounds of interest. A rigid HPLC system may end up costing more money in the long run when it's time to scale up or change processes. An inflexible HPLC system means that scientists must adapt their experiments to system constraints when ideally, the HPLC system should adapt to your productivity needs.

In this article, you’ll learn about the advantages of modular HPLC systems when it comes to current experimental needs and how the ability to swap out HPLC components safeguards the future of your system and your research.

Advantages of Modular HPLC Systems

The ability to mix and match components of an HPLC system is important for several reasons:

Flexibility & Customization: Different scientific applications and goals require specific HPLC configurations. You often need to tailor HPLC components to meet the unique requirements of the experiments. For example, an analytical HPLC system may be able to run small purification jobs but with higher risks of losing compounds due to a thinner fluidic path.

Cost-Effectiveness: HPLC systems can be expensive, and scientists like you may have limited budgets. While the initial cost of an integrated HPLC system may be lower than a modular system, a modular system allows you to future-proof your HPLC system in cases where your purification process or application changes. By mixing and matching components, you can optimize your systems for specific applications without the need to purchase an entirely new system. This can be a cost-effective way to expand the capabilities of your lab.

Performance Optimization: Different components in an HPLC system can affect its performance in terms of resolution, sensitivity, and throughput. Scientists may need to experiment with various combinations of columns, detectors, and pumps to achieve the best results for their specific challenges. For example, optimizing the performance of the HPLC system specific to your application could mean selecting a different column type (ex: reverse phase, ion exchange) or column diameter. It could also mean using a different detector or pump, or tweaking the conditions for separation such as flow rate, injection volume, etc., to adapt with the chosen column.

Upgrading Existing Systems for Scale-up: HPLC systems are meant to last a long time, but technological advances continually improve HPLC components, mainly columns. Laboratories often have existing HPLC systems and upgrading them with new components can extend the life and functionality of these systems. We recently highlighted an example of this in our case study with the Institute for Research and Innovation in Biomedicine, which showed how our VERITY® 271 HPLC system helped them scale up peptide purification.

Method Development: Scientists may need to develop new chromatographic methods to purify specific compounds. Mixing and matching components, such as adding multiple columns selection, allows them to fine-tune their HPLC systems to achieve the required separation in a shorter time.

Sample Compatibility: Different samples may require different HPLC conditions, and not all components suit all sample types. A flexible HPLC system allows scientists to select components that are compatible with the physical and chemical properties of their samples.

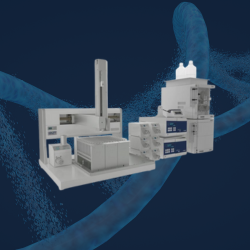

We Understand You Need Flexible Systems - Meet the VERITY® HPLC Systems

Our VERITY® HPLC Systems offer many features to enhance the flexibility and adaptability of HPLC experiments. Those characteristics are highlighted in Our HPLC Systems, such as the VERITY® 271 HPLC System or the VERITY® Oligonucleotide Purification System which allow you to mix and match components to select detectors, pumps, columns, racks, consumables, and other accessories that best suit your lab needs. This flexibility means you can selectively upgrade parts of the system as technology advances rather than replace the entire system.